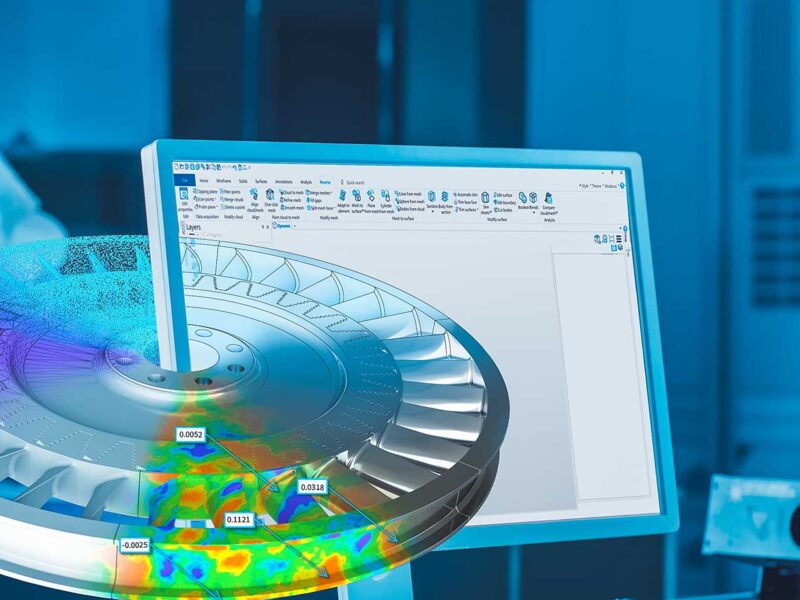

Reverse engineering has grown in importance over the past few decades as an essential part of product design and production processes utilized by businesses worldwide. Industrial engineers and product designers use reverse engineering to replicate a legacy part without documentation or blueprints, analyze and disassemble a competing product, or alter and improve an existing one in a variety of industries, including aerospace, automotive, and daily consumer goods. The hardware and software used to convert real components or assemblies into solid, accurate, and dependable computer-aided design (CAD) models advance with technology. The future of reverse engineering is being shaped by new metrology sensors, more powerful software made possible by quicker and less expensive computers, and advancements in AI. These factors will allow reverse engineering to have more potential uses and become more widely available.

The majority of today’s items go through several versions prior to being released off the production line. This iterative process, known as “rapid” or “fast” prototyping, describes methods for creating physical models or prototypes of a product or component as soon as feasible in order to simulate the final product design. Rapid prototyping has emerged as the preferred technique for manufacturers in recent times to verify and test design concepts before mass production, hence reducing the possibility of expensive errors and delays.

In this process, reverse engineering is essential because it helps businesses build digital representations of components or products that already exist, which serve as the foundation for quick prototyping

As virtualization becomes more popular, 3D measurement technologies will become more in demand.

Many of businesses have already included additive manufacturing in their routines for reverse engineering. For example, before going to the manufacturing stage, shoe producers use portable 3D measurement technology to take pictures of the older models, make changes, and 3D print them to see how the new model would seem and behave. In order to replace missing parts for vehicles and facilitate prototypes, automotive restoration businesses are implementing additive manufacturing. Utilizing reverse-engineered patient scan data, several hospitals—including veterinary hospitals—integrate 3D printers to create customized orthotic and prosthetic devices.

Many of businesses have already included additive manufacturing in their routines for reverse engineering. For example, before going to the manufacturing stage, shoe producers use portable 3D measurement technology to take pictures of the older models, make changes, and 3D print them to see how the new model would seem and behave. In order to replace missing parts for vehicles and facilitate prototypes, automotive restoration businesses are implementing additive manufacturing. Utilizing reverse-engineered patient scan data, several hospitals—including veterinary hospitals—integrate 3D printers to create customized orthotic and prosthetic devices.